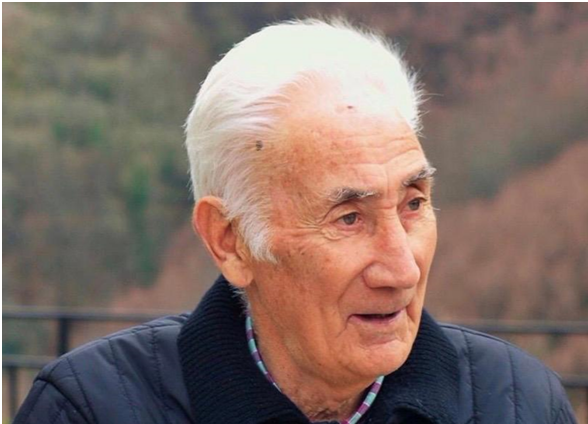

When Juan José Astigarraga created the first trestle in 1983 for the French market, he surely could not have imagined the magnitude of his project. What started out in a small workshop has grown into two production facilities of more than 15,000 m2, a team of 120 people and a distribution network with 5,000 customers throughout Europe. An expert on the depths of forests, Juan José left four years ago, having previously passed the baton to his four children, but above all else managing to uphold values like endeavour, hard work, confidence and enthusiasm in the next generation.

His daughter, Itziar Astigarraga, chairwoman of the board of directors and co-founder of the company, has a sparkle in her eyes when she talks about her father. She misses the founder’s “laughter” and his “positive and dynamic” personality. Her eyes still sparkle when she mentions her sister and brothers: Izaskun, Jose Juan and Izaro. She reveres her family and confesses her admiration for them. Four essential pillars uphold the legacy of enterprise, hard work and dedication that their father instilled in them. This is an interview with Itziar Astigarraga on principles and ethics, not forgetting the activity that defines Astigarraga Kit Line: the design and manufacture of ecological, natural wood furniture and storage products. It is possible to be profitable and sustainable.

40 years of history with the same values

-The germ of Astigarraga Kit Line has a name: Juan José Astigarraga. What do you remember about those first steps your father took?

-We did not witness the first steps because our father started his professional career in forestry around 1950. He had a wealth of knowledge: he bought forests of different types of trees, subcontracting logging crews and sawmills to turn all this wood into raw material for his customers; mainly furniture and packaging manufacturers. Around 1981 there was a major crisis in the furniture sector that affected many of its customers.

It is said that out of great crises come great opportunities. He, who was a very enterprising and dynamic person, immediately saw one: to make use of the raw material of which he was expert, creating a small workshop for the manufacture of wooden trestles. Between 1981 and 1983 he was lucky enough to meet the man who was to become the distributor of the trestles in France: Garoa.

-What a practical and simple product! And what’s more, you are born international?

-Our father had a stroke of luck because from his first day as a trestle maker he was international. The first trestles he made were for the French market.

Expansion and consolidation in foreign markets

-The market evolves and the company has to adapt to new circumstances. From manufacturing only wooden trestles, the company diversifies into new products and markets. And here, you have a lot to do…

-Between 1983 and 1985, the relationship with Garoa was consolidated because our father proved that he had a great capacity to manufacture the quantity of trestles that were ordered weekly as well as guarantee quality. He was aware that the French market was very demanding and did not hesitate to buy the machinery he needed.

At home, I wanted to get to know my father’s work and in 1983 I joined the company. I spent two years in the factory and in 1985 I began to forge a close relationship with Garoa, who asked us if we would be able to manufacture shelving and bottle racks for the French market.That was when we saw that the foundation, and the most important part – knowledge and experience – was guaranteed. What did we need to to do meet this demand? Design the shelves and bottle racks and purchase the machinery. And so we set to work on the design. Until 1986, 100% of the production of these two new products was for the French market.

-When will the season be open to other markets?

-In 1986, seeing that we had the capacity to manufacture various products, we decided to open a commercial network in Spain, as we had recognised that the DIY store sector was opening up in Spain. That was when we started to expand throughout the country, with a more comprehensive catalogue full of creativity: we diversified our supply with new ranges of solid pine wood trestles, shelves and wine racks. It was a new challenge for our young company, with extraordinary results. To take this big step, we expanded our industrial facilities.

In 1988, sales began in Germany, and in 1989, the first Leroy Merlin shop was opened in Madrid with the implementation of the entire portfolio. From 1990 onwards, a period of expansion and consolidation began in Spain, France, Portugal, Belgium, Germany and Denmark. In 1997, we began to penetrate another market: Italy. And in 2001, we became a leading manufacturer of trestles, thanks to the opening of a new industrial hall.

-With the 2008 crisis, was there a mixed bag?

-On the one hand, this crisis badly affected sales in the country, but on the other, it made Astigarraga Kit Line stronger. The internationalisation project we had launched began to bear fruit: in 2008, 80% of our turnover was generated in Spain, with 20% in other markets, while in 2018, the percentages were reversed. We were already established in France and we went on to build strong sales teams in Italy and Germany, doubling our sales figures.

The first generation bursts onto the scene

-Is it a challenge to move from the first to the second generation?

-It has been a natural process. Year by year, we were entering new countries, and the brothers joined us. In the beginning, our brother Jose Juan, who followed in the footsteps of our father, both in manufacturing operations and in his eagerness to get out into the woods to learn the skills of the forestry profession. In 1991, Izaskun, who is now the financial manager, took over responsibility for the health of the financial resources. In 2001, Izaro joined, who has managed to create a solid marketing team -the promotional engine of the company- of which she is now the director and in which she develops new products and leads the commercial teams.

-And maintaining the same enthusiasm that your father and his values exuded, is that another challenge?

-The four brothers started our career in the company with a common denominator: that the passion for wood and the enthusiasm for the company remain strong. Our father passed this on to us: to believe in the project, to be enthusiastic about it, and for trust to prevail between us and with the rest of the people in the organisation. But he went further: he ensured that this trust was also passed on to the companies that worked with him. The forest owners, the loggers, the sawmill owners, the transporters, the hardware suppliers… they all had complete confidence in him. And that is what he conveyed to us from the very beginning and what we still believe in and try to pass on to the people who work with us today: the importance of trust in a long-term relationship.

Our success, the team

-Does the saying ‘like father, like son’ hold true?

-We have tried to do so. In our case, it is 100% compliant. We four siblings dedicated body and soul to the project our father gave life to, with those eyes that were always full of enthusiasm. We are now working on the process of conveying this hope to the next generations; three people at the moment, but above all to the whole Astigarraga Kit Line team. A company cannot be understood without enthusiasm, confidence, encouragement, security?

-And without people it is not understandable either…

– That’s right. The success of Astigarraga Kit Line is thanks to the whole team. There are more than 120 of us, including management, sales teams, marketing, administration, plant workers… People have been so loyal to our company’s project that in recent years people who started right back at the very beginning are now retiring. We must be grateful and appreciate how fortunate we are that our father was accompanied by people who shared his values.

-Enthusiasm, confidence and another of your father’s values was honesty. He had a phrase that he used to repeat a lot…

– When you give your word, keep it. The word is sacred… He used to say it a lot to all his collaborators. He did not need any paper, he knew that documents were necessary, but he was one of those who said that what was agreed verbally was sacred.

-Have all these values remained constant over time or have they varied over time?

-We will continue to pass them on to the next generations. This is another of the company’s successes. He also never failed to remind us of the importance of having the ability to make sacrifices, because only then does reward come. Understood as dedication, putting enthusiasm into the project and work.

-The reward for this sacrifice and hard work, overcoming crises and making changes in strategy, came in July 2021, when the company received the Business Internationalisation Award from the Gipuzkoa Chamber of Commerce… The importance that the brand has had in its expansion strategy is obvious…

-We are an exporting company from day one. All the effort the company had made was rewarded in the form of this award, and at a very special time… The international markets are very demanding, and to meet their demands we have made a great effort to attract and retain human and technological resources.

-What other countries do you have your sights set on?

-In northern European countries, in those countries with a culture where wooden products bring back the essence of nature, making home life more pleasant and cosy, and where peace and well-being are in the air. Selling to countries that don’t appreciate wood makes no sense at all, it’s like going to sell umbrellas in the desert.

-What is the company doing to minimise the activity of designing and manufacturing solid pine furniture?

-At Astigarraga Kit Line we always say that our raison d’être is wood. We own the entire value chain: we buy forest, fell it, process the logs into boards in the sawmill, dry the wood naturally in the fields, and in the production halls we manufacture the various products in the catalogue. In other words, we apply the circular economy throughout the entire value chain, from the sourcing of raw materials to the marketing of our products. All the wood is extracted from the surrounding forests of Gipuzkoa and Bizkaia. 100% of the wood is sourced from these local forests. And 100% of it is used for other purposes: for biomass or for paper mills.

There must be consistency between who we are, what we say we are and what we do. We take care of the forests through very selective pruning. And we only fell the pines at their most mature stage, when their life cycle is over, respecting their natural growth. Always with a commitment to reforestation.

-The wood they use is locally sourced and, most importantly, certified.

-Timber certificates are a forestry and environmental guarantee. Since 2005, all our products have been PEFC-certified, which guarantees that the raw material is legally sourced from sustainably managed forests. Another milestone was the achievement in 2019 of the European Ecolabel, which promotes the circular economy by encouraging manufacturers to generate less waste and CO2 throughout the production process.

-He has almost 40 years of experience. What do you think differentiates you from your competitors?

-In addition to using local and ecological wood and owning the entire value chain, we have a capacity for innovation in product design, always providing a valuable solution to the needs of customers and consumers. We offer a wide range of products: What does an easel have to do with a tidy box? Also, the ability to distribute directly to customers and, above all, the close relationship with them. Customer service is essential.

Against glass ceilings

-If you talk through the different production plants, through the offices, or if you slip into a Management Committee or Board of Directors meeting, there are women. Are there more and more women in top management positions or is the glass ceiling still a reality?

-In Astigarraga Kit Line since its beginnings, no distinction has been made between men and women. There are women in the manufacturing units as well as in the other areas, because of their value. The percentage of women has always been high, because “genderless” and unbiased talent prevails. We have always been committed to knowledge and skills, regardless of gender. Both in senior management positions and in the rest of the workforce, the ratio is even. But it is true that, in general, this does not happen very often.

– With your experience, how do you see the wood sector and its future expectations?

– Wood is a natural, efficient, economical, ecological and above all renewable, reusable and recyclable resource. The advantages of using wood are innumerable. But our obligation and duty is to make good use of it, i.e. we must continue to optimise the great potential of wood as a raw material. Our sector generates employment and wealth; in this sense, our great desire is to generate wealth within, and for, the timber sector in the Basque Country. And we are also a sector that is committed to sustainable forest management, digitalisation and the circular economy. And only in this way, under quality and control standards, will we be able to preserve this precious resource.

Innovation and digitalisation

-Finally, what is your projection for Astigarraga Kit Line for the next 10 years?

-We are putting all possible efforts into the two main pillars –innovation and digitalisation– by increasing investments in these fields in order to optimise industrial production processes. Innovation has been one of the levers we have pursued throughout our history, but I am not just talking about technology, I am talking about the willingness to look for new ways of doing things in order to progress, and this is essential to be innovative. At the same time, digitalisation is another lever that we consider essential to achieve internal and external growth, as the digital revolution is transforming the world and it is important for the company to be on this train.

Companies have to grow in a sustainable, but also profitable way to guarantee a stable future for the workers and all the companies that are relying on us: local suppliers of the environment, distributors, farmers who own the forests and more.

We will also work on the development of new products that will allow us to continue building and shaping that exciting adventure that our father devised in a small workshop 40 years ago, that dream that he started and that all of us who are part of the company continue to share with enthusiasm.